Many serious shooters, especially handloaders use a chronograph to measure the velocity of bullets. This allows you to get a better understanding of what the bullets you're shooting are actually doing. Ammunition manufacturers and reloading manuals provide velocity data, but the only way to see what ammunition really does in your gun is to measure it yourself.

Up until recently, most chronographs used optical sensors to calculate velocity. These devices work but have some disadvantages:

- They must be placed in front of the firing line. So, if you're on a range with other people you need to coordinate setup and teardown, and tweaking the position.

- Because they're in front of the gun, they are at risk of being hit. This is not uncommon. I know a couple people who've shot their chronographs.

- They can be finicky depending on the lighting. Sometimes it's too bright. Other times it's too dim. Very shiny bullets may not register well. (A potential fix for that is to color them with a black marker.)

Several years ago the Lab Radar chronograph was introduced, using Doppler RADAR to calculate velocities. From what I've read it works well. More recently, Garmin came out with the Xero C1 Pro Chronograph, which also uses Doppler RADAR. I bought one last week and tried it for the first time on Wednesday. I am completely blown away by it.

The only criticism I have so far of the Garmin is that it doesn't come with a carrying case, so I got one of these for it.

Here's a picture of the Garmin on the shooting bench at my club along with a couple of the guns I shot. That little thing on the tripod is the entire unit.

A close up:

According to the instructions that Garmin shipped, when measuring pistol bullet velocity you should have the pistol 5" - 15" over the unit. When shooting a rifle, it should be 5" - 15" to the side and behind the muzzle. Also, the bullet needs to be able to travel at least 20 yards to the target.

The bottom of the unit is threaded to accept a standard 1/4-20 camera tripod mount, so if where you shoot doesn't have a suitable bench, you have an alternative. I've also seen mounts that allow you to attach it to a rifle.

I fired a total of 70 rounds over the Garmin with no errors. Before going to the range I downloaded the Garmin ShotView app to my iPhone 12. The app and the unit sync via Bluetooth.

I measured several different handloads in a variety of revolvers.

Colt Police Positive with 4" barrel in .32 Smith & Wesson Long

- 96 grain RNFP from Desperado Cowboy Bullets

- 3.8 grains of Alliant Unique

- Servicios Aventuras small pistol primer

- PPU brass

- Average muzzle velocity: 1058 FPS

- Average muzzle energy: 239 ft. lbs.

I was surprised at how fast this load shot, although it's not maximum according to some data I've seen. It wasn't particularly pleasant to shoot in the little Colt.

S&W Model 1905 Military & Police, 4th Change in .32-20 (.32 WCF).

- 96 grain RNFP from Desperado Cowboy Bullets

- 4.7 grains of Winchester AutoComp

- CCI small pistol primer

- Starline brass

- Average muzzle velocity: 746 FPS

- Average muzzle energy: 119 ft. lbs.

The low velocity surprised me here. AutoComp is specifically designed to generate a lot of gas for pistols fitted with compensators. As such, it's rather blasty. I'll be figuring out other loads to use, probably with Bullseye and/or HP-38.

Next up were some .38 Special full charge wadcutters in two guns, a S&W Model 64-2 .38 with a 1-7/8" barrel, and a Model 66-3 .357 Magnum with a 4" barrel.

Model 64-2 in .38 Special

- 148 grain #35891 button-nose, bevel-base wadcutter from Matt's bullets

- 3.5 grains Alliant Bullseye

- Winchester wadcutter brass

- Average muzzle velocity: 757 FPS

- Average muzzle energy: 188 ft. lbs.

I also fired the same load in the Model 66-3 in .357 Magnum.

- Average muzzle velocity: 844 FPS

- Average muzzle energy: 234 ft. lbs.

You can see that the longer barrel gives an extra 87 FPS and 46 ft. lbs. of energy.

Most standard pressure .38 Special 158 grain loads give around 750 FPS from a 4" barreled revolver. I had a box of .38s loaded with a Speer 158 grain LSWC on top of 3.5 grains of Bullseye. Let's see how they did in the two K-Frames:

Model 64-2 snub:

- Average muzzle velocity: 680 FPS

- Average muzzle energy: 163 ft. lbs.

Model 66-3:

- Average muzzle velocity: 774 FPS

- Average muzzle energy: 210 ft. lbs.

That's a noticeable difference. This load is quite comfortable to shoot in a K-Frame.

Last up were some .38 Specials loaded to duplicate the power of the .38/44, which was the predecessor of the .357 Magnum. Note that this load develops +P or +P+ level pressures and should never be fired in J-Frame or K-Frame .38 Special revolvers, or comparable guns from other makers. It should only be fired in guns chambered for .357 Magnum, or old S&W .38/44s or guns designed to handle these loads. I shot them in the Model 66-3 .357 Magnum.

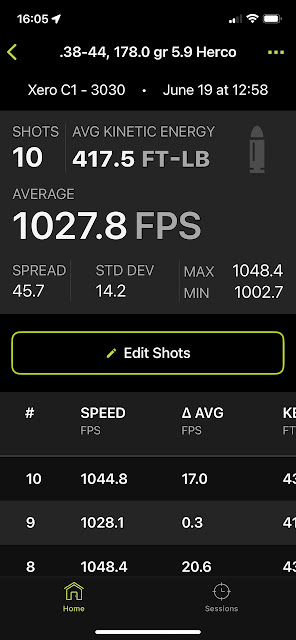

Model 66-3:

- 178 grain #358429 Keith from Matt's bullets

- 5.9 grains of Alliant Herco

- Winchester Small Pistol primer

- Mixed brass

- Average muzzle velocity: 1028 FPS

- Average muzzle energy: 417.5 ft. lbs.

For the IPSC shooters, this load has a power factor of 183, so it easily makes major. This would make an excellent load for a woods walking gun, good for defense against most animals in the Lower 48 states.

The original .38/44 factory loads all used 158 grain bullets at 1125 FPS from a 6.5" barrel. I'm planning to load some with the same 5.9 grains of Herco under a 158 grain LSWC. I bet they'll get close to the original ballistics.